New technology tested in Sunshine Coast waters will soon be installed for three Vancouver Island fish farms to help reduce the spread of sea lice.

On Feb. 8, Grieg Seafood BC Ltd. announced it would launch its new system at its three fish farms in the Esperanza Inlet, off the west coast of Vancouver Island.

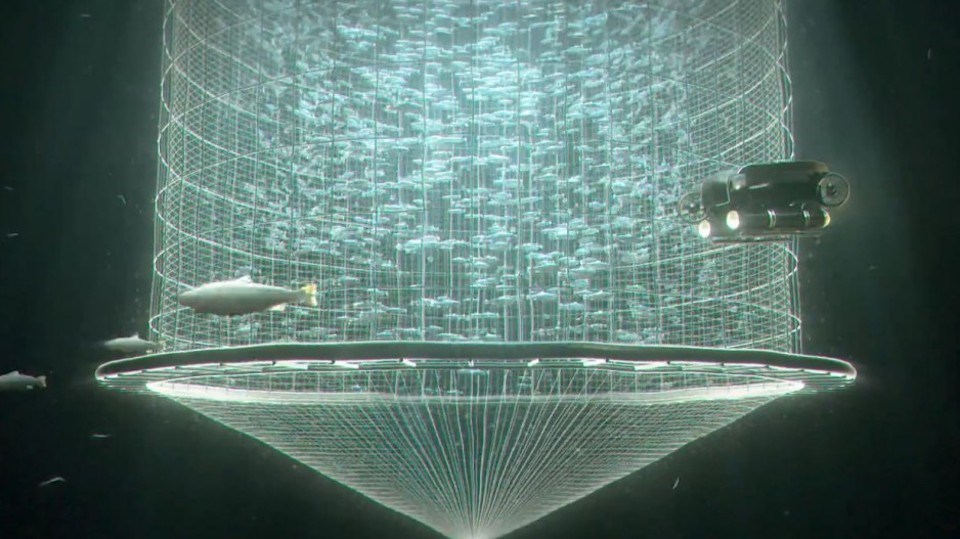

The first trial for the made-in-B.C. system began in 2019 at Grieg’s Culloden farm located in Sechelt Inlet, and was looking for ways to mitigate harmful algae. The CO2L Flow (pronounced “cool flow”) system lets farmers raise or lower barriers around the fish farm enclosure to a depth of 15 metres, to respond to natural ocean conditions. The barriers are paired with a nanobubble technology that sustains the oxygen levels and water quality and makes sure the water continues to circulate. It was developed with CPI Equipment Ltd. of Nanaimo, Poseidon Ocean Systems of Campbell River and international company Oxzo Technologies.

Over the course of one and a half years, the trial recorded an average 13 per cent improvement in feed conversion ratios, a reflection of the fish’s ability to convert food into body mass. The trial also saw survival rates increase by 19 per cent, according to a press release. Compared to fish in a nearby traditional system, the CO2L flow reported improved growth sometimes up to a full kilogram, Grieg’s communications director Amy Jonsson told Coast Reporter via email.

A press release from the company says three generations of fish at the Sunshine Coast farm were successfully reared with the system.

Jonsson said one of the biggest successes the trial saw was the prevention of lateral interaction between wild and farmed fish, by lowering the barriers of the new system.

“This has benefits for both populations in that it stops the ability of lice to transfer between wild and farmed, and also greatly reduces the need to treat the farmed salmon for sea lice. The barriers also limit the ability of harmful or toxic algae from being able to enter the farm and affect our fish,” she said.

Since water is still able to flow in and out of the system, it does not stop the movement of pathogens. At this time, the system also does not collect solid waste, something Grieg’s press release said the company is continuing to look for a solution for.

Each system costs about $2 million, and costs can vary depending on the site specific natural conditions of each farm. It can be adapted to the existing farm sites. The new technology will be in place for the duration of the upcoming farming cycle at the Steamer Point farm, Lutes Creek farm and Esperanza farm.

“At this time, we only have the one system at our Culloden site, and look forward to these new systems being completed and in the water for 2023,” Jonsson said.

“As a company, Grieg is really proud of the system, and the strong support we have received. We look forward to the next phase and the introduction of Poseidon Ocean System and Oxzo [Technologies] to the team to help us to continue to improve the system.”

Grieg has nine farming licenses on the Sunshine Coast. Five of nine farm licenses are active and Aquaculture Stewardship Council (ASC) and Best Aquaculture Practices (BAP) certified at Salten, Vantage, Site 13, Ahlstrom and Culloden, and the remaining four – Newcomb, Site 9, Kunechin and Paradise Bay – are inactive.