I recently finished a piece for Canadian Geographic on the burgeoning Carbon Capture Utilization and Storage (CCUS) landscape in Canada. It’s a fascinating industry and a bit of a technological Wild West, with brainy entrepreneurs, characters galore, nervousness around proprietary technology (some companies wouldn’t even talk to me), big promises, lots of hype, equivocal press and… not the greatest performance record.

But it won’t be like that for long. Refinement and deployment of CCUS is ramping up, driven by federal and provincial carbon pricing and promised tax credits (in related news, tax credits for carbon-capture as well as speed of implementation appeared in President Joe Biden’s bazillion-dollar Inflation Reduction Act recently passed in the U.S.).

CCUS comprises a suite of technologies that capture CO2 from high-emitting point-sources like industrial and power facilities, or directly from the atmosphere (Direct Air Capture or DAC). The captured CO2 is compressed and transported to either be permanently sequestered underground, employed in processes like Enhanced Oil Recovery (where pressurized CO2 is pumped into the ground to push remaining oil out of aging wells), or used to create products like concrete, fizzy drinks and low-carbon synthetic fuels. All of this serves to lower emissions of the processes involved. In fact, CCUS can theoretically deliver negative emissions when more carbon gets stored than what’s emitted capturing it.

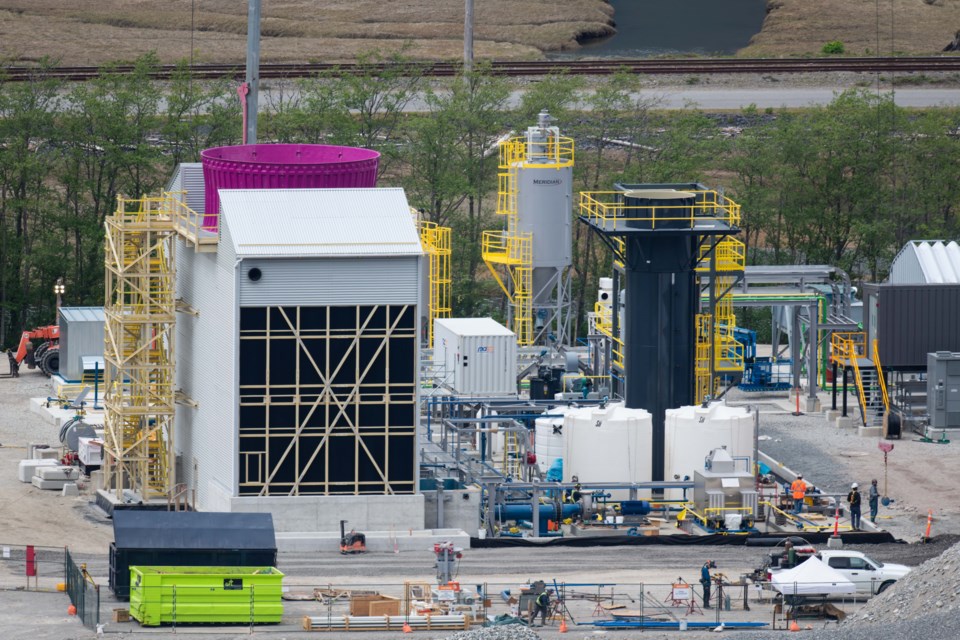

My first move was to find out more about DAC at local success story Carbon Engineering (CE), a small Canadian company that has erected North America’s first viable DAC facility on the Squamish waterfront. There I found a small, fenced-in area containing a low, corrugated-roof building, a few small towers, a giant fan, and plenty of piping. Several hundred metres away stands a more expansive modern building whose infrastructure identifies it as a much-enlarged and improved version of the former. From modest pilot plant to showy Innovation Centre, this dichotomy represents CE’s evolution.

CE was founded in 2009 by Harvard professor David Keith. Scouring CO2 from air was, at the time, seen as a far-fetched “moonshot,” because concentrations of the gas are 300 times lower than in the industrial sources typically used for carbon-capture. But Keith persisted. With $3 million in seed money (thank you Bill Gates and Calgary Flames owner Murray Edwards), he acquired a small, mothballed chemical plant on the Squamish foreshore. CE captured its first CO2 in 2015, and produced its first clean fuel in 2017.

Vice President and head of Business Development, Lori Guetre, has invited me for a walkaround, but before we don hard hats and safety vests, we settle into a boardroom for a math lesson. Globally, we release some 35 to 40 billion tonnes (gigatonnes, or Gt) of CO2 into Earth’s atmosphere annually. Currently we’re capturing only ~0.1 per cent of that—a pittance compared to the 10 Gt/yr of removal necessary to ensure planetary warming doesn’t exceed 1.5 C by 2050. If DAC can be scaled up to contribute a projected 1 Gt/yr to this total, that leaves 9 Gt/yr to be captured and stored via other means from industries fuelled by biomass, natural gas, oil and coal. Is this even possible?

“It’s not can we,” says Guetre. “It’s will we. We have the tech to do it now. But we don’t have 30 years to invent new stuff. So the question is how do we marshal the cheapest and fastest carbon-capture processes already in use?”

Most climate thinkers believe that achieving emission reductions through less reliance on fossil fuels remains job one—but that it’s hard to see a future in which carbon-capture doesn’t play some role. Not only must we scale up all CCUS, deploy it globally, and bring it to bear on building a carbon-neutral economy, notes Guetre, but also on mopping up the enormity of legacy CO2 accrued over the past 200 years, during which atmospheric concentrations increased from a livable 280 ppm that stood for six millennia, to a frightening and—as we’re experiencing—powerful 420 ppm.

Guetre harbours no illusions about the immensity of this challenge. “We’re currently adding 2 ppm per year. So if you look at the remaining carbon budget before 1.5 degrees of warming occurs, we have less than 7.5 years before crossing that threshold at 430 ppm. To get back to a ‘safe’ level of CO2—about 350 ppm—we need to remove about one trillion tonnes of legacy CO2 from the atmosphere. We’re definitely in trouble.”

As we head outside, she notes how scaled-up DAC is the missing piece in the carbon abatement puzzle. “It’s cheaper than alternatives, almost infinitely scalable, and can capture emissions from any point in time,” she says. “In the near term, if we capture five to 10 Gt/yr the price would be around $300/tonne; but if we get that down to $100, the cost of achieving net-zero could drop from eight per cent of global GDP to half that—saving trillions.”

How does CE’s tech work? Clever chemistry and off-the-shelf equipment from other industrial sectors play equal parts: giant fans spin ambient air through a contactor where CO2 is captured in a chemical reaction to produce potassium carbonate, which is sent to a reactor where the carbon is transferred into calcium carbonate pellets; these go to a final unit where high heat strips off pure CO2. All reactions involve non-toxic, non-volatile chemicals in closed-loop systems where each compound is reconstituted and used again. Modularity of the system, and the ability to locate plants anywhere, mean it can be scaled up safely to take advantage of low-cost renewable energy and proximity to sequestration sites, CO2 pipelines or centres of industrial demand.

CE’s first large-scale commercial facility is being developed in west Texas with American partner 1PointFive. “We’d like this first plant to demonstrate how megatonne-scale DAC is feasible, affordable, and available,” says Guetre, of CE’s vision of fleets of 1 Mt/yr DAC facilities working alongside renewable electricity, energy efficiency and other innovations in all economic sectors to tackle the climate crisis.

That sounded like a grand idea to me.

Leslie Anthony is a biologist, writer and author of several popular books on environmental science.

.jpg;w=120;h=80;mode=crop)